30.08.2023

FUTURE® S AIR HANDLING UNIT WITH VERTICAL OUTPUT

The Future® S air handling unit has been designed to meet the latest energy efficiency requirements. In the Future® S product series, all connections are located on top of the unit to allow as much floor space as possible for other purposes.

The product series includes four unit sizes, the largest of which can reach an air volume of 2,000 l/s. Each Future® S unit size includes two heat recovery options: a rotor or a counterflow cell. The Future® S air handling unit and the broad range of available automation equipment and accessories guarantee the right solution for every need.

four unit sizes: S500 – S900 –

S1200 – S1800

Air flow range

0.15 – 2 m3/s

Air handling unit with vertical output

S500, S900 and S1200 delivered in one piece; S1800 in modules

Rotor and counterflow heat recovery

-

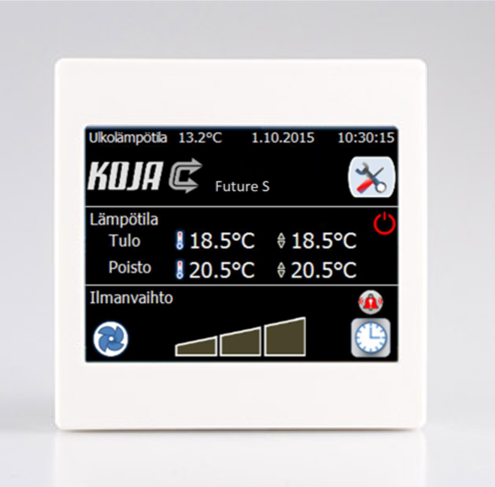

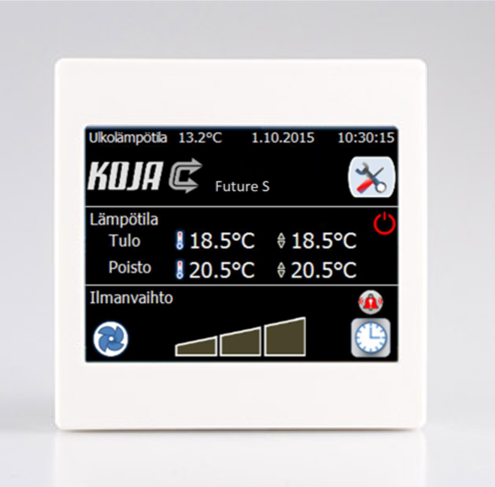

ELECTRICAL AND AUTOMATION EQUIPMENT

Option 1. Fidelix FxVent control

-

Factory installed and tested automation system with field devices

-

Covers all air handling unit control and monitoring functions

-

Colour 3,5” touchscreen

-

Modbus RTU connection to building automation

-

Available in Finnish, Swedish and English

Option 2. Terminal block machine

-

The field devices are pre-installed and - wired to the terminal blocks in the machine’s electrical and automation unit.

-

The unit is controlled by a building automation system.

-

-

PUMP GROUPS

By adjusting the size of the pump groups with the help of the Future®++ selection program, you can ensure the optimal operation of the designed coil and the suitability of the related components. We deliver the pump group as a complete system, which saves time on site and guarantees a compact and well-functioning solution.

- Use the easy-to-use Future®++ selection program to ensure an optimal and energy efficient coil and pump group unit.

- The pump groups are delivered as a separate package; pin plugs in the electrical and automation cables.

- The heating groups contain a highly efficient Grundfos Magna3 circulation pump and a Belimo valve with actuator.

- The heating groups are made from painted steel.

- The groups are pressure-tested at 8 bar at the factory.

- Comprehensive machine run documentation

-

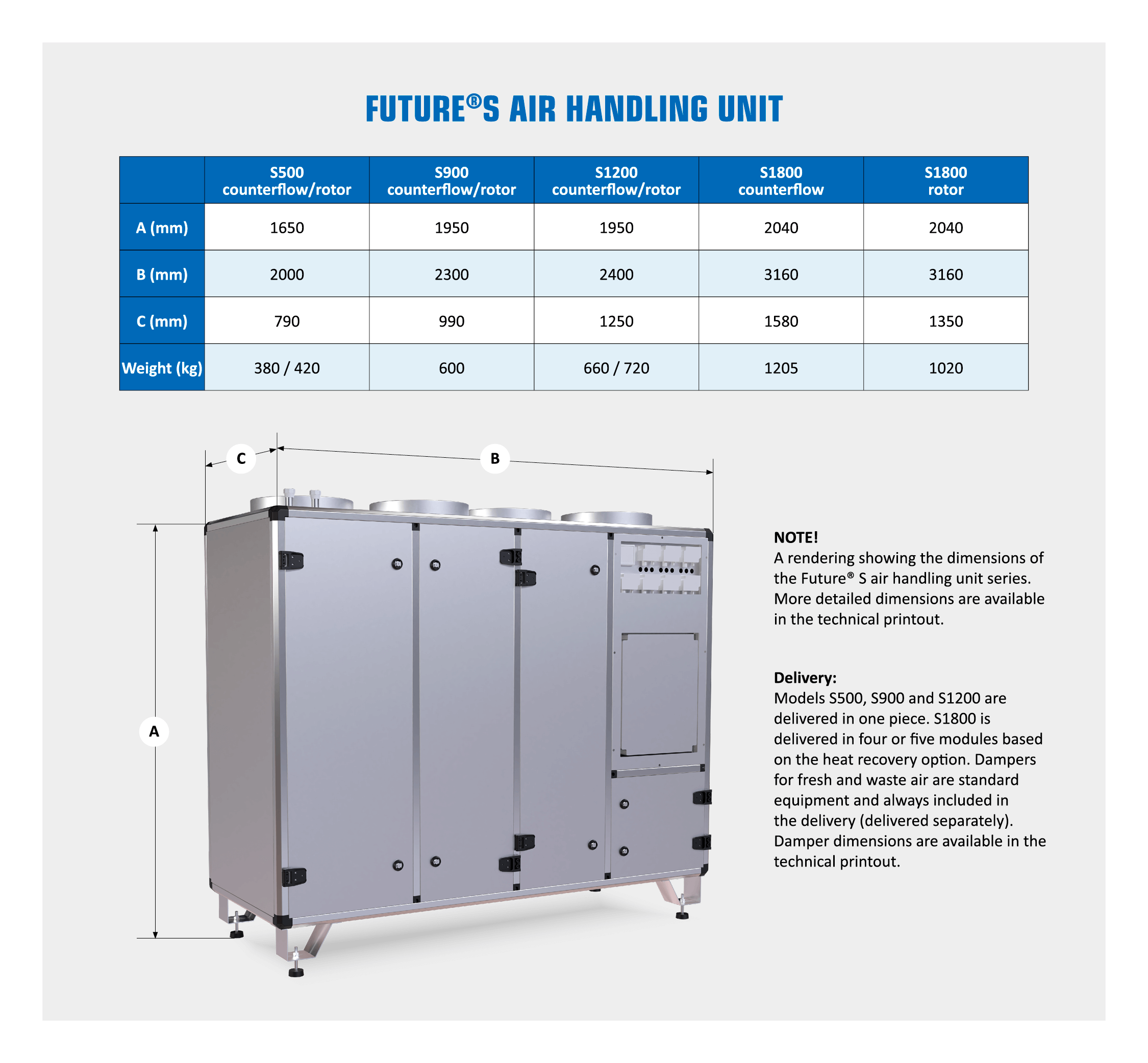

DELIVERY, INSTALLATION AND DIMENSIONS

Future® S500, S900 and S1200 are delivered in one piece. Future® S1800 is delivered in four or five modules based on the heat recovery option. The dimensions of the units can be found in the table below, and more detailed in the technical printout available from the selection program.

-

STANDARD EQUIPMENT

- Energy efficient and silent EC fans of the IE5 energy class

- Rotor and counterflow heat recovery

- Liquid circulation post-heating coil

- Long bag filters: a large filtration area and low pressure loss throughout filter life

- Supply filter ePM1 60%, exhaust filter ePM10 60%

- The field devices are pre-installed and - wired to the integrated electrical and automation unit.

- Adjustable base, water outlets and seals, hoist brackets, safety switch, spare filters.

REFERENCES

Koja has long experience in various projects for optimizing conditions and ventilation. The focus is on customer experience and smooth operation with our partners. Check out the success stories of our customers and you will also know more about Koja's vast expertise.

GET IN TOUCH

Ask about our air handling products, energy modernization services and selection programs. Our team of experts is here to help.