13.09.2023

KOJA’S EXPERTISE IN HEAT RECOVERY SYSTEMS PLAYS A VISIBLE ROLE IN LANTMÄNNEN AGRO’S ENERGY SAVING INVESTMENT

Lantmännen Agro Oy is taking the energy efficiency of its feed factories in Kouvola and Ylivieska to a brand-new level. With the aid of Koja’s Industrial Next integrated service, the cooling conditions remain optimal during the feed manufacturing process, and the waste heat created can be recovered and used.

When the energy efficiency at Lantmännen Agro’s feed factories was studied, energy saving and optimizing cooling by utilizing heat recovery became the key goals from the start. A great amount of heated steam is used for heat treatment in feed manufacturing, and most of the thermal energy in the steam usually ends up in the outside air through supply fans in feed cooling, resulting in waste heat. In addition to energy savings, waste heat can also be used to standardize cooling, which has a significant impact on the quality of the final product.

‘Energy efficiency, the improved quality of the end product and reducing waste are megatrends every company aims to achieve. It’s great to be offering our customers solutions that truly have an impact on society,’ says Vesa Aalto, Koja’s Business Area Manager.

SIGNIFICANT BENEFITS TO CUSTOMERS AND A MORE FLUENT PROCESS WITH KOJA INDUSTRIAL NEXT INTEGRATED SOLUTION

‘As a company, Koja is strongly committed to reducing emissions and energy consumption in industry, buildings and on ships. Our principle is to provide an efficient route to our customers in terms of green transition and the productivity of our customers’ business,’ explains Pasi Lähteinen, Koja Industrial Solutions’ Business Director.

Koja has developed a new integrated solution, Industrial Next, which is specifically designed for energy saving, heat recovery, condition control and process-technical improvement in industrial applications. The Industrial Next solution is always planned in cooperation with customers, and the concept covers initial review, survey, reporting, planning, implementation and follow-up.

Until now, Lantmännen Agro's feed factories have had a varied practice in controlling the cooling air and preheating it in winter.

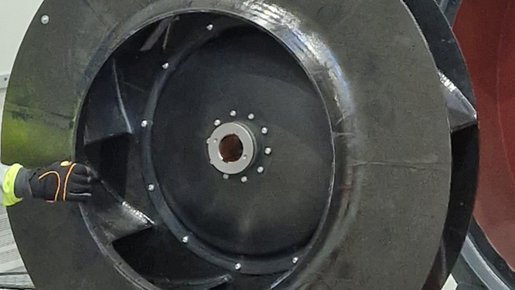

The new solution by Koja consists of modular heat recovery and supply air modules with Future structures and modern automation. The heat recovery modules replace the exhaust diffusers of the pelletising lines on the roof of the feed factories. In addition to heat recovery coils, the heat recovery modules include filter and by-pass functions to address any fault situations in process filtration.

Meanwhile, the supply modules are installed on the ground floor, where the supply air inlet for the pelletising lines is currently located. They include grids that separate water and snow, G4 grade coarse-grain filters and a combi coil for heating or cooling the supply air, depending on the season. A water-cooling unit by Chiller Oy, which is part of the Koja Group, makes cooling even more efficient. The supply air flow is controlled by supply fans manufactured by Koja Industrial Solutions.

The automation system helps adjust the valves of the combi coil, as well as the rotation speed of the supply air fans. All this ensures that the functions and conditions at the feed factory remain optimal, regardless of the season, outside temperatures and weather conditions. Also, most of the waste heat is recovered.

The heat recovery system produces up to 1 MW of heating power, and the total energy recovered annually at the feed factories is approximately 3,000 MWh.

A SIGNIFICANT ADDITION TO KOJA’S SERVICES

Koja can use its expertise on a particularly wide scale at Lantmännen Agro’s sites and can update well-known general air conditioning solutions to suit industrial applications. In addition to Koja’s equipment, the site includes equipment by Koja’s sister company, Chiller. The project is also a significant opportunity because it is Koja’s first large-scale process technology project within the field of food industry.

‘In cooperation with customers like Lantmännen Agro, we are capable of major environmental acts while improving the productivity and quality of our customers’ processes,’ concludes Lähteinen.

‘We congratulate Lantmännen Agro for their excellent choice of service providers and thank them for the opportunity to implement such a significant project. As for our own project team, I want to wish them good luck with the project. Let’s get the most out of this and learn something for the future,’ says Aalto.